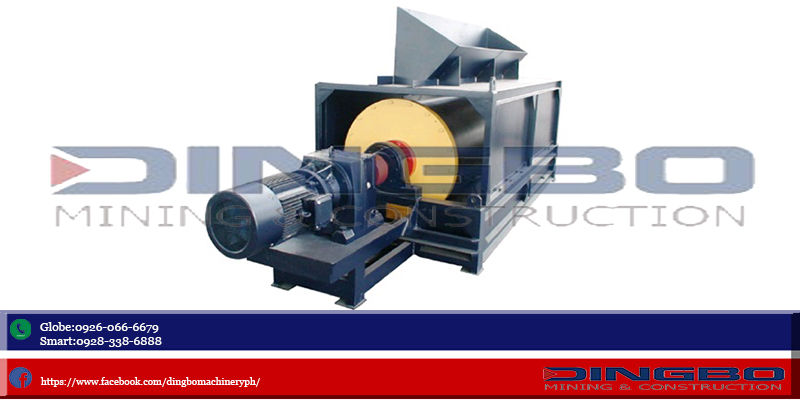

Our company has developed a magnetic separator roomates can be installed directly in the head of the belt conveyor and can be configured as a separate cleaning magnetic separator. It is mainly used to select the low taste of ore, improve the grinding taste and reduce the cost of selecting ore. It can also be applied to non-magnetic materials except iron. How it works: when the pulp is poured into the tank, the ore is loose in the flow of the water to the tank. In the role of the magnetic field, the magnetic magnetic mineral grains occur together and form "magnetic group" or "magnetic chain" "magnetic group" or "magnetic chain" in the pulp by the magnetic force function, the movement to the poles, and adsorb on the cylinder. Due to the polarity of the magnetic poles along the cylinder rotate direction interwoven, and fixed at work, magnetic group "or" magnetic chain "in the cylinder rotates, with alternating polarity magnetic stirring, was mixed in the" magnetic group "or" magnetic chain "of the gangue and other non-magnetic minerals in a turn off, has finally been sucked on the surface of the cylinder, the "magnetic group" or "magnetic lotus" is concentrate. Concentrate on the cylinder to the edge of the magnetic magnetic department the weakest place, under the effect of discharge hoses ore, washing water is discharge to concentrate in the slot, if it is full of magnetic magnetic roller, mine was conducted with the brush roll. Non-magnetic or weak magnetic minerals in the pulp with pulp discharge groove, known as tailings. was mixed in the "magnetic group" or "magnetic chain" of the gangue and other non-magnetic minerals in a turn off, has finally been sucked on the surface of the cylinder, the "magnetic group" or "magnetic lotus" is concentrate. Concentrate on the cylinder to the edge of the magnetic magnetic department the weakest place, under the effect of discharge hoses ore, washing water is discharge to concentrate in the slot, if it is full of magnetic magnetic roller, mine was conducted with the brush roll. Non-magnetic or weak magnetic minerals in the pulp with pulp discharge groove, known as tailings. was mixed in the "magnetic group" or "magnetic chain" of the gangue and other non-magnetic minerals in a turn off, has finally been sucked on the surface of the cylinder, the "magnetic group" or "magnetic lotus" is concentrate. Concentrate on the cylinder to the edge of the magnetic magnetic department the weakest place, under the effect of discharge hoses ore, washing water is discharge to concentrate in the slot, if it is full of magnetic magnetic roller, mine was conducted with the brush roll. Non-magnetic or weak magnetic minerals in the pulp with pulp discharge groove, known as tailings. washing water is discharge to concentrate in the slot, if it is full of magnetic magnetic roller, mine was conducted with the brush roll. Non-magnetic or weak magnetic minerals in the pulp with pulp discharge groove, known as tailings. washing water is discharge to concentrate in the slot, if it is full of magnetic magnetic roller, mine was conducted with the brush roll. Non-magnetic or weak magnetic minerals in the pulp with pulp discharge groove, known as tailings.

Magnetic system is compounded of ferrite and the permanent magnets; The average magnetic induction intensity of cylinder surface is 100 ~ 600mT.The same cylinder can be equipped with three types of tanks adapting to different dressing process. Small area taken, good separation for magnetic minerals, reduce the load of the next process. Permanent magnetic drum separators have three kinds Including downstream type, counter flow type and semi-counter flow type According to the difference of the base structure. Downstream types of permanent magnetic drum separator: sIurrv flows in the same direction with the drum.

Counter flow type permanent magnetic drum separator: the slurry flows over against the drum, the which create great conditions for cleaning of non-magnetic ores. The non-magnetic ores approach the clean surface of the drum and the magnetic ores can be absorbed in the strongest magnetic field. Semi-counter flow type permanent magnetic drum separator: the slurry is fed into the cavity from the bottom of the drum, and the magnetic ores fall into concentrate tank after reaching A Certain height, while the non-magnetic ores will enter into tailings tank along with slurry in the opposite direction with the drum.

Magnetic Separator

PAYMENT TERM:

30% Advance Payment By T/T

70% Payment Before Shipment T/T

Port Pick Up (MANILA/CEBU/DAVAO)

We Will Provide Photos of the Parts and the Packaging Before The Goods Are Ready to be Shipped.

DELIVERY TIME:

We Can Dispatch The Machine Out of the Seller's Factory Within 30 Working days after recipt of the advance Payment.

WARRANTY:

100% Brand New, 100% Good Quality, 1 Year Warranty.